Table of Contents

What Is Geotechnial Drilling?

Geotechnical drilling is a site investigation technique designed to uncover the physical properties surrounding a construction site. Also known as geotechnical boring, this process involves evaluating the soil, rock, groundwater, and overall conditions within a given depth and location.

Geotechnical drilling objectives

In any geotechnical site investigation project the driller’s objective is to observe and record all relevant information about the soil, rock, or water table, provide samples, and carry out downhole tests as requested by the project engineer or geologist. Some specific tasks and objectives might include:

• Take ‘disturbed’ and ‘undisturbed’ samples of sand, clay, gravel, rock, and fill materials.

• Locate the water table and take water samples.

• Take ‘undisturbed’ samples of fine-grained materials for laboratory tests.

• Perform in-hole tests.

• Locate hard strata.

• Identify bedrock and prove it for a specific depth.

• Provide core for detailed examination of rock quality.

• Provide details and interpretation of drill behaviour.

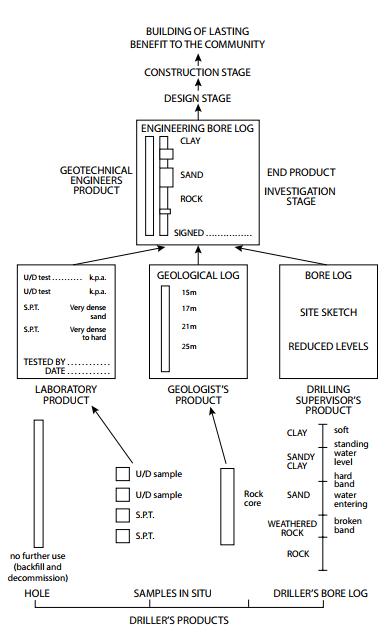

How the geotechnical driller’s work is passed on

Before a large building can be safely and economically designed, detailed knowledge must be obtained on the soil or rock on which it will rest.

The design is a job for an engineer, but the collection of subsurface information required is a job for a

specialised driller, the geotechnical driller, who works in a team with other specialists such as geologists and

geotechnical engineers.

Geotechnical driller’s useful products

drilling a hole is only a means to an end. The hole itself is of no permanent value. The important thing is the quality of the information that comes from the hole.

The best information is obtained from a continuous sample that is an undisturbed ‘slice’ from the ‘layer cake’ making up the foundation materials at the site.

Unfortunately the act of removing a sample from its environment results in some distortion, even if only by a change in the pressure holding the grains together.

By very careful sampling using specially designed thin wall tubes, a sample with very little distortion can

be obtained. Such samples are termed ‘undisturbed samples’. Because of the time and care involved in

extracting these samples, they are very costly.

The provision of ‘undisturbed samples’ in a continuous sequence usually cannot be justified, and less costly sampling procedures must be adopted. Intermittent taking of ‘undisturbed samples’ provides samples for laboratory analysis at key levels.

The more economical sampling method used for the bulk of site investigation drilling provides samples

known as ‘disturbed samples’. These have some distortion but can be readily interpreted with confidence

by trained personnel using standard techniques.

The permanent result of this process is the hard copy information that it provides, that is, bore logs and results of analyses on bore and fluid samples.

The samples themselves may have a brief life, and they certainly cannot be attached to the report.

Choosing the type of geotechnical drilling

1. Category A: Achieved while drilling is in progress:

• disturbed sampling

• locating hard strata

• locating the water table

• recognizing features of drill behaviour

• taking rock core.

2. Category B: Make use of the hole when drilling is stopped:

• taking ‘undisturbed samples’

• performing ‘in situ’ tests (standard penetration tests, etc.)

• collecting water samples and measuring the standing (static) water level (SWL).

The best type of drilling for site investigation is one that enables the driller to provide useful products of the highest quality at economical rates of operation. The choice of drilling type is therefore very important. It must be chosen so that while drilling proceeds, good quality disturbed samples (or rock cores) are produced, hard or wet strata are identified, and the driller is able to make accurate, meaningful observations of the behaviour of the drill.

The drilling technique and hole stabilization method used must ensure that the hole is stable and the hole bottom is clean so that testing or sampling is not fouled up by loose material.

Although some requirements may result in selecting a single obvious drilling method (e.g. a core drill for rock coring), other requirements may be satisfied to varying degrees by many different types of drilling. For example, locating hard stratum is straightforward and can be accomplished by all the currently acceptable types of drilling.

The driller relies largely on disturbed samples to produce his log of the soil profile from the ground surface to rock level. How accurate his bore log information is will depend on the quality of the samples he produces. The quality of the ‘disturbed samples’ produced varies greatly with the type of drilling employed.

The effects of geotechnical drilling on the quality of the obtained sample

Making a hole: Whatever type(s) of drilling you use to make the hole, there will always be some disturbance

of the formation material as it is removed from the face by the drill bit.

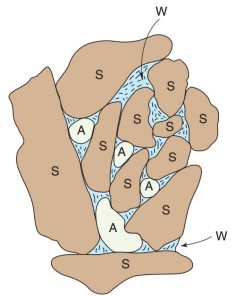

The cuttings may be prised out in large chunks, pared off in slices, ground to a powder, fractured into chips,

sucked up vertically in sausage-like lumps, or dislodged by several other techniques available.

Hole clearing: Clearing the cuttings from the hole also affects the quality of the samples, because the

samples may be mechanically disturbed by the bit and drill string. Wetting, drying, or contamination by the hole-clearing fluid, gravity separation on the way to the surface, and other factors will alter the samples.

All types of drilling have been used at one time or another for site investigation, even though they may

have been quite unsuitable for the project and formation being drilled.

Of all the types of drilling that the driller can use to penetrate the formation, the best one for site investigation purposes will be the one that produces the most recognizable ‘disturbed samples’. It will produce the sample least disturbed and least contaminated.

Appropriate types of geotechnical drilling

Cable Tool

When it comes to providing the best ‘disturbed samples’, cable-tool drilling is ideal for this purpose because the ‘drive-and-extract’ technique provides excellent samples. This technique involves advancing the borehole by driving a cylindrical tube into the soil and then extracting it.

Clays and silts and sometimes thin interbeds of sand can be extracted using an earth socket, drilling dry, and can be examined in the slots at each side of the socket before clearing it out.

Sands and gravels can be caught in casing that is driven a meter or two and pulled out again with a strong winch. While this involves a certain amount of tedious redrilling of part of the hole after each drive, the technique will provide large amounts of samples from particular depth intervals.

Augers: When hand augers are carefully operated they can provide a sample that is only slightly disturbed.

Basically it is a short hollow tube or ‘bucket auger’ with cutting edges at the bottom. Large chunks of clay can be taken from the auger and examined to see soil texture. Whole samples of sand above the water table can be successfully taken with hand augers to considerable depths. Hand augers of this type can be used to advance a test hole to a certain depth, with a final core taken by a drive socket. The drive socket is driven by hand using a slide hammer. These tools are good for initial reconnaissance of a site.

Large diameter plate and bucket power augers can obtain large chunk soil samples to shallow depths and can often allow visual inspection in the borehole.

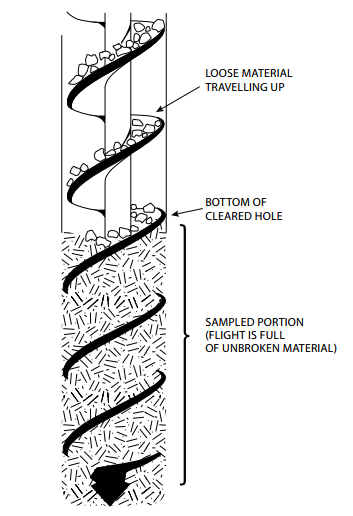

Continuous flight augers are one of the most popular types of tool for investigation drilling. With solid flight augers, accurate sampling is possible in suitable formations using special techniques.

Accurate hole logging requires a technique of lifting at fairly short intervals to check the sample at the bit.

This sample is usually slightly twisted, but after cleaning the outside surface, soil texture and other

properties can easily be seen. As the sample feeds up the flights it becomes heated, distorted, and mixed with materials from the side of the hole. This sample is much less reliable than the lifted sample.

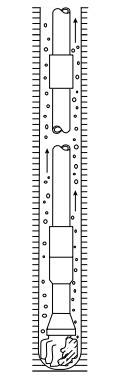

Another popular site investigation auger tool is the hollow stem auger. Using the hollow stem methods,

standard geotechnical testing procedures can be used, such as determining soil resistance by counting hammer blows on split spoon samplers.

When necessary, the engineer will request more ‘core’-type sampling, such as thin-wall tubes and standard penetration tests (even continuously down the full depth of the borehole) to overcome the problems of poor ‘disturbed’ samples.

Solid tube samplers and wireline core barrels can be used inside a hollow auger system. In rock lithology situations, various rotary methods are chosen.

Rotary drilling with air flushing: This type of drilling provides a good indication of material being drilled. This is particularly so when done with a blade bit and in fairly dry formations, where sample return is almost instantaneous. In some situations, drying out of the sample may occur.

Samples may be collected in such a way to provide the equivalent of a core by dropping samples into a tube.

Rotary drilling with clear water flushing: This type of drilling is generally suitable to identify strata, providing the bit in use will give cuttings of sufficient size. For example, a blade bit may be satisfactory, whereas a roller bit might not.

Colour changes are readily discernible, but soil texture and moisture content are destroyed. As the hole gets deeper, there is a greater time lag before cuttings arrive at the surface.

Dual tube air flush drilling: This dual tube type of drilling in sands and alluvial materials provides rapid

return of continuous whole samples. Its use is somewhat restricted in engineering site investigation since casing may have to be run to allow undisturbed sampling.

A distinct advantage of this drilling type is its ability to drill through lost circulation zones, which would be impossible using open-hole methods, at depths impractical for typical hollow stem auger rigs.

Diamond coring: This is by far the most common method of drilling and sampling consolidated and semiconsolidated formations.

| Geotechnical Drilling Objective | Cable | Auger | Core | Air Rotary | Dual Tube |

|---|---|---|---|---|---|

| Disturbed Sampling of Sand Above water table | Yes | Yes | Yes | ||

| Disturbed Sampling of Sand Below water table | Yes | Yes | Yes | ||

| Disturbed Sampling of Clay Above water table | Yes | Yes | Yes | Yes | Yes |

| Disturbed Sampling of Clay Below water table | Yes | Yes | Yes | Yes | Yes |

| Disturbed Sampling of Gravel, boulders, clay | Yes | Yes | |||

| Disturbed Sampling of Deep alluvial deposits (incl. sand, silt, clay, and gravels) | Yes | Yes | Yes | Yes | |

| Disturbed Sampling of Fill | Yes | Yes | Yes | Yes | |

| In situ testing of formation Penetration tests in soils | Yes | Yes | Yes | Yes | |

| In situ testing of formation Permeability tests in rock | Yes | Yes | |||

| Undisturbed sampling of fine grain soils | Yes | Yes | Yes | Yes | Yes |

| Location of water table | Yes | Yes | Yes | Yes | |

| Location of hard stratum | Yes | Yes | Yes | Yes | Yes |

| Identification of rock | Yes | Yes | Yes | Yes | |

| Proving rock to specific depth | Yes | Yes | Yes | Yes | |

| Provision of rock core for examination | Yes |